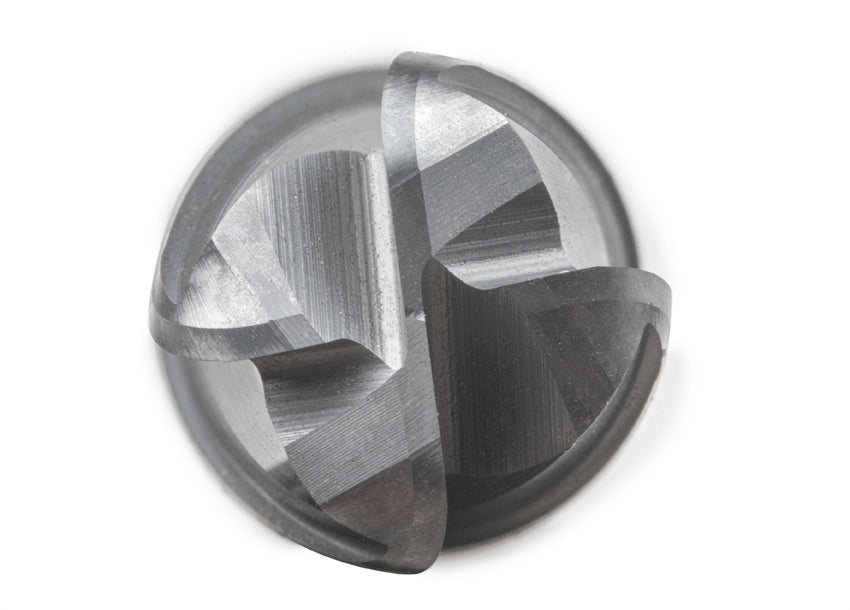

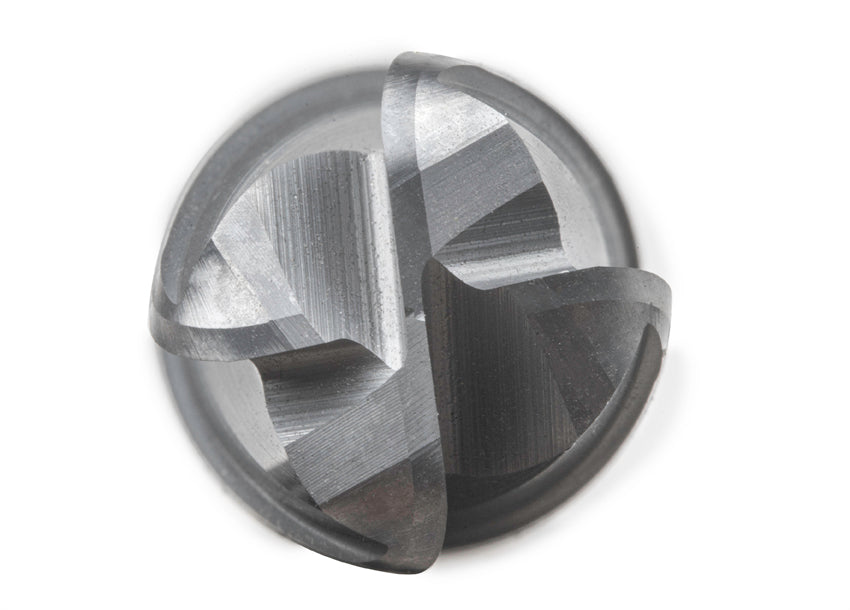

Izar 9446 CROMAX-Coated Solid Carbide Radius Endmill | 4-Flute R1.00 Unequal Helix DIN 6528 N

Izar 9446 CROMAX-Coated Solid Carbide Radius Endmill | 4-Flute R1.00 Unequal Helix DIN 6528 N

The Izar 9446 is a high-precision radius (corner-rounding) solid carbide endmill made from UF micro-grain carbide, featuring 4 flutes, a 1.00 mm corner radius, and an unequal-variable helix (IKRA) for excellent vibration dampening. Built to DIN 6528 N specifications and equipped with a flat shank, this tool delivers smoother finishes and enhanced tool stability—especially on challenging materials such as alloy steels, stainless steels, and copper alloys.

Geometry & Benefits

-

1.00 mm corner radius: Strengthens the cutting edge, distributes load, improves tool life, and yields smoother surface finishes on vertical faces.

-

Unequal-variable helix (IKRA): Suppresses chatter by breaking up harmonics, offering high fidelity surface finish and vibration-free operation.

-

UF micro-grain carbide: Delivers outstanding rigidity, edge durability, and resistance to wear—a solid choice for precision machining.

-

4-flute setup: Enhances tool strength while facilitating efficient chip removal, balancing rigidity with material evacuation.

-

DIN 6528 N standard geometry: Delivers predictable, repeatable results compatible with standard toolholders and machining routines.

Applications & Material Suitability

Perfect for operations that demand surface quality and precision:

-

Finishing profiling and corner rounding on materials like alloyed steels, heat-treatable steels, stainless steels, and copper/brass.

-

Suitable for high-speed CNC operations where chatter suppression and edge retention matter.

-

Ideal for components requiring smooth transitions between surfaces, such as molds, die cavities, aerospace parts, and marine components.

Recommended Feeds & Speeds (Material-Specific)

| Material Group | Feed (mm/rev) | Cutting Speed (Vc, m/min) |

|---|---|---|

| Alloyed Steel (<300 HB) | 0.070 | 112–150 |

| Heat-Treatable Alloyed Steel (300–400 HB) | 0.056 | 60–130 |

| Austenitic Stainless (<250 HB) | 0.049 | 50–80 |

| Ferritic/Martensitic Stainless (<320 HB) | 0.035 | 100–130 |

| Copper/Bronze/Brass (short or long chips) | 0.084 | 140–350 |

| Titanium Alloys (Ti-6Al-4V) | 0.030 | 70–90 |

| Inconel 718 | 0.030 | 100–130 |

8mm, Cutting length 19mm, 63mm OAL, CR1mm, 8mm Shank

8mm, Cutting length 19mm, 63mm OAL, CR2mm, 8mm Shank

10mm, Cutting length 22mm, 72mm OAL, CR1mm, 10mm Shank

10mm, Cutting length 22mm, 72mm OAL, CR2mm, 10mm Shank

10mm, Cutting length 22mm, 72mm OAL, CR3mm, 10mm Shank

12mm, Cutting length 26mm, 83mm OAL, CR1mm, 12mm Shank

10mm, Cutting length 22mm, 83mm OAL, CR2mm, 12mm Shank

10mm, Cutting length 22mm, 83mm OAL, CR3mm, 12mm Shank

Couldn't load pickup availability

Low stock: 1 left

View full details