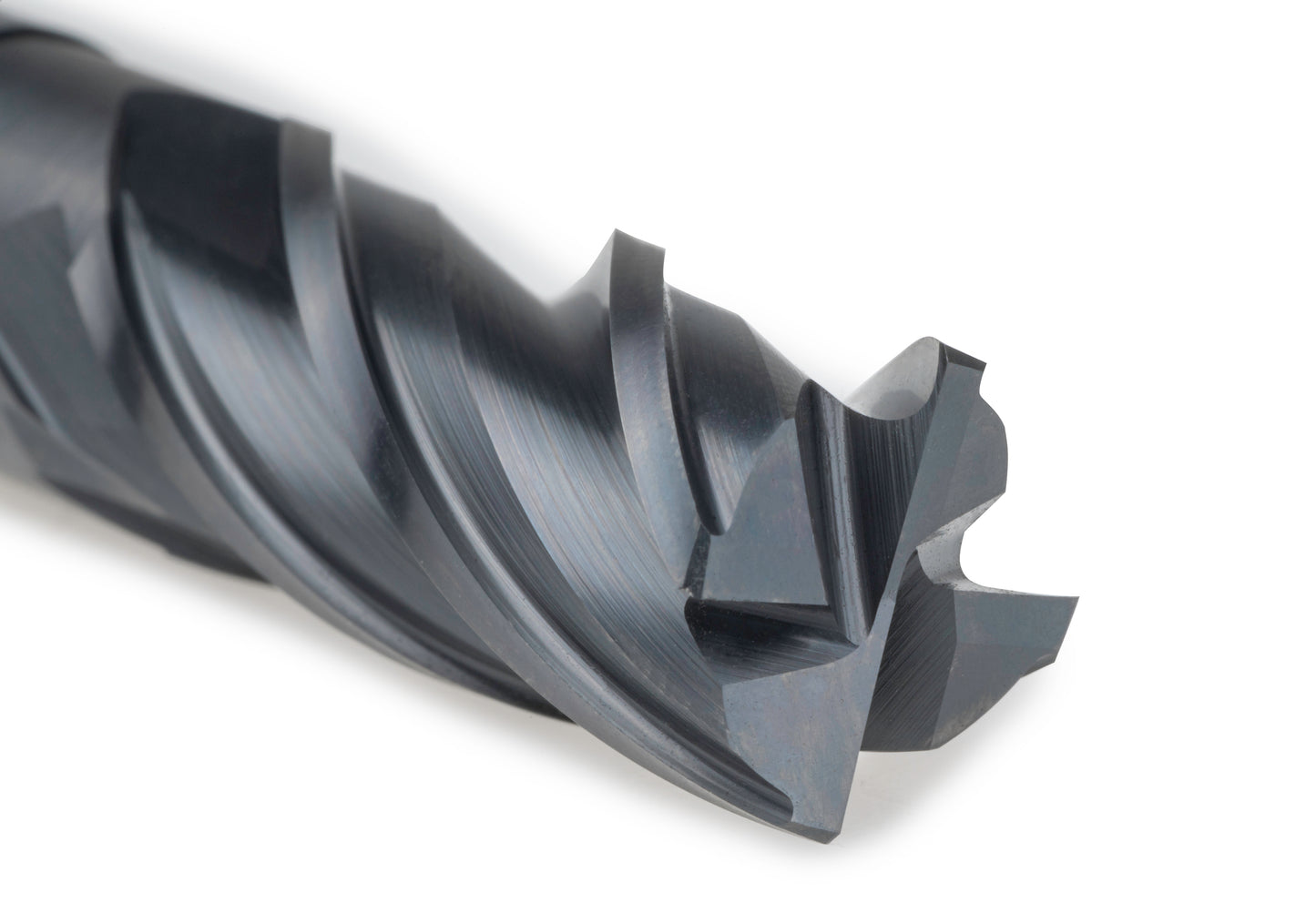

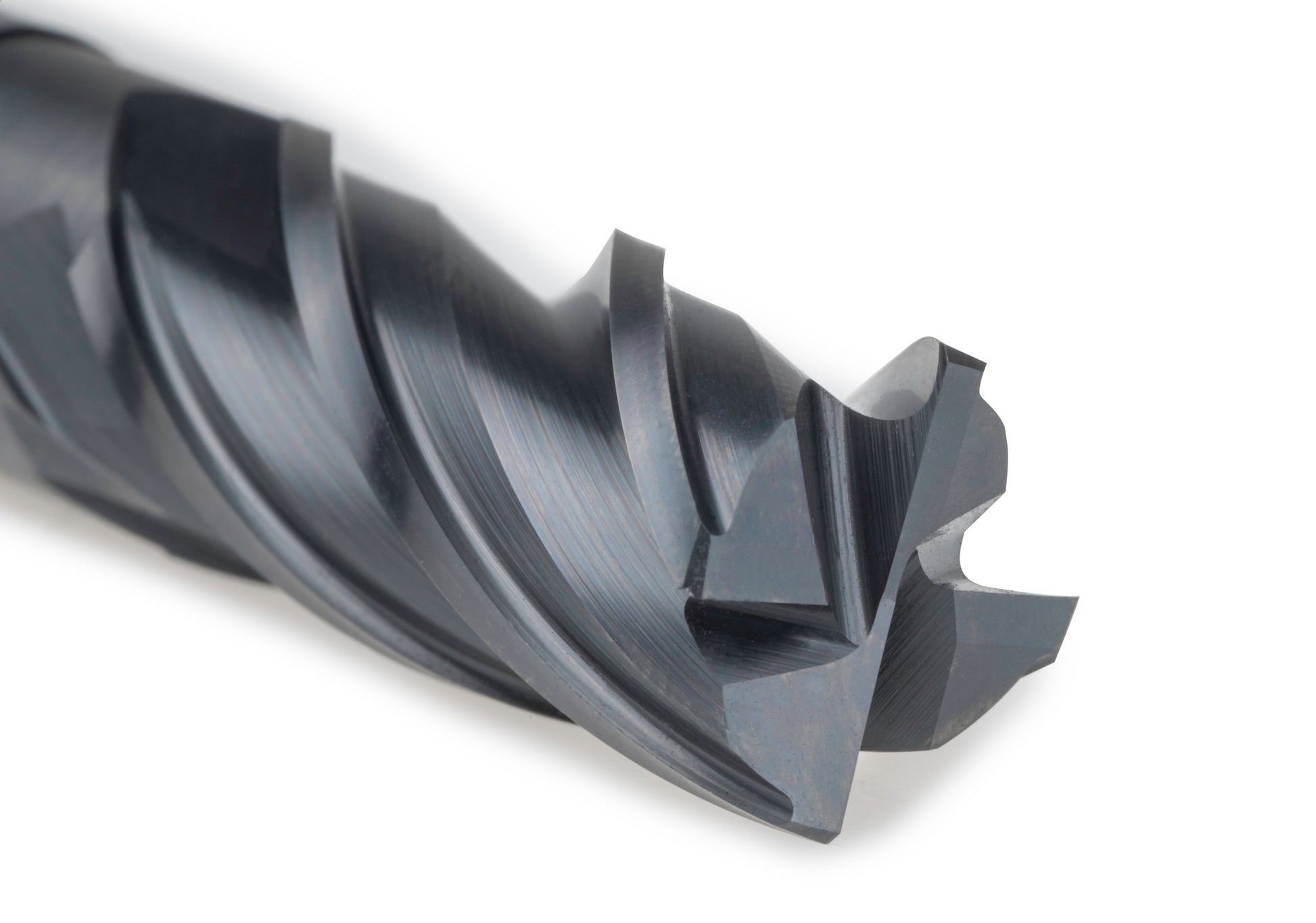

Izar 9406 — Solid Carbide Finishing Endmill (4-Flute, Variable/Unequal Helix, CROMAX-Coated, DIN 6528 N)

Izar 9406 — Solid Carbide Finishing Endmill (4-Flute, Variable/Unequal Helix, CROMAX-Coated, DIN 6528 N)

The Izar 9406 is a premium solid carbide finishing endmill designed for smooth, chatter-free milling across a broad range of materials. Its 4-flute UF micro-carbide body pairs with an unequal-variable helix (IKRA) for noise and vibration reduction, while the CROMAX coating ensures low friction and long tool life. Available in diameters from Ø2 mm up to Ø20 mm, all with a flat shank, this tool is ideal for high-performance finishing in production environments.

Geometry & Benefits

-

Unequal-variable helix (IKRA): The irregular helix disrupts harmonics and reduces chatter—yielding superior surface finish and allowing higher feed rates.

-

4-Flute layout: Maximizes rigidity and ensures smooth, fine finishing with high material removal control.

-

Solid UF micro-grain carbide: Offers excellent stiffness and wear performance, essential for precision and tool lifetime.

-

CROMAX coating: Lowers friction, heat, and abrasion—well-suited to challenging materials like stainless, alloyed steels, and cast iron.

-

DIN 6528 N standard: Standardized geometry offers consistent, interchangeable performance in production tooling systems.

Applications & Material Capability

Designed for exceptional performance across challenging materials:

-

Alloyed and heat-treatable steels, stainless steel (austenitic and martensitic), cast iron, titanium alloys, and copper/brass.

-

Common applications include finish milling, contouring, and profiling where surface finish, dimensional control, and tool life are critical.

-

The unequal helix excels in high-speed CNC environments where chatter must be suppressed.

Recommended Feeds & Speeds

Here’s a quick reference for machinists:

| Material | Cutting Speed (Vc) (m/min) | Feed (mm/rev) |

|---|---|---|

| Alloyed Steel (<300 HB) | 112–150 | 0.056 |

| Heat-treatable Alloyed Steel (300–400 HB) | 60–130 | 0.050 |

| Austenitic Stainless (<250 HB) | 50–80 | 0.049 |

| Ferritic/Martensitic Stainless (<320 HB) | 100–130 | 0.035 |

| Cast Iron (<200 HB) | 60–80 | 0.056 |

| Cast Iron (200–300 HB) | 40–60 | 0.056 |

| Titanium Alloys | 50–68 | 0.028 |

| Copper/Bronze/Brass (short or long chip) | 140–350 | 0.070 |

5mm, Cutting length 13mm, 50mm OAL, 5mm Shank

6mm, Cutting length 13mm, 57mm OAL, 6mm Shank

8mm, Cutting length 19mm, 63mm OAL, 8mm Shank

10mm, Cutting length 22mm, 72mm OAL, 10mm Shank

12mm, Cutting length 26mm, 83mm OAL, 12mm Shank

Couldn't load pickup availability

Low stock: 2 left

View full details