Izar 9401 CROMAX-Coated Solid Carbide Endmill | 4-Flute 30° Helix DIN 6528 N

Izar 9401 CROMAX-Coated Solid Carbide Endmill | 4-Flute 30° Helix DIN 6528 N

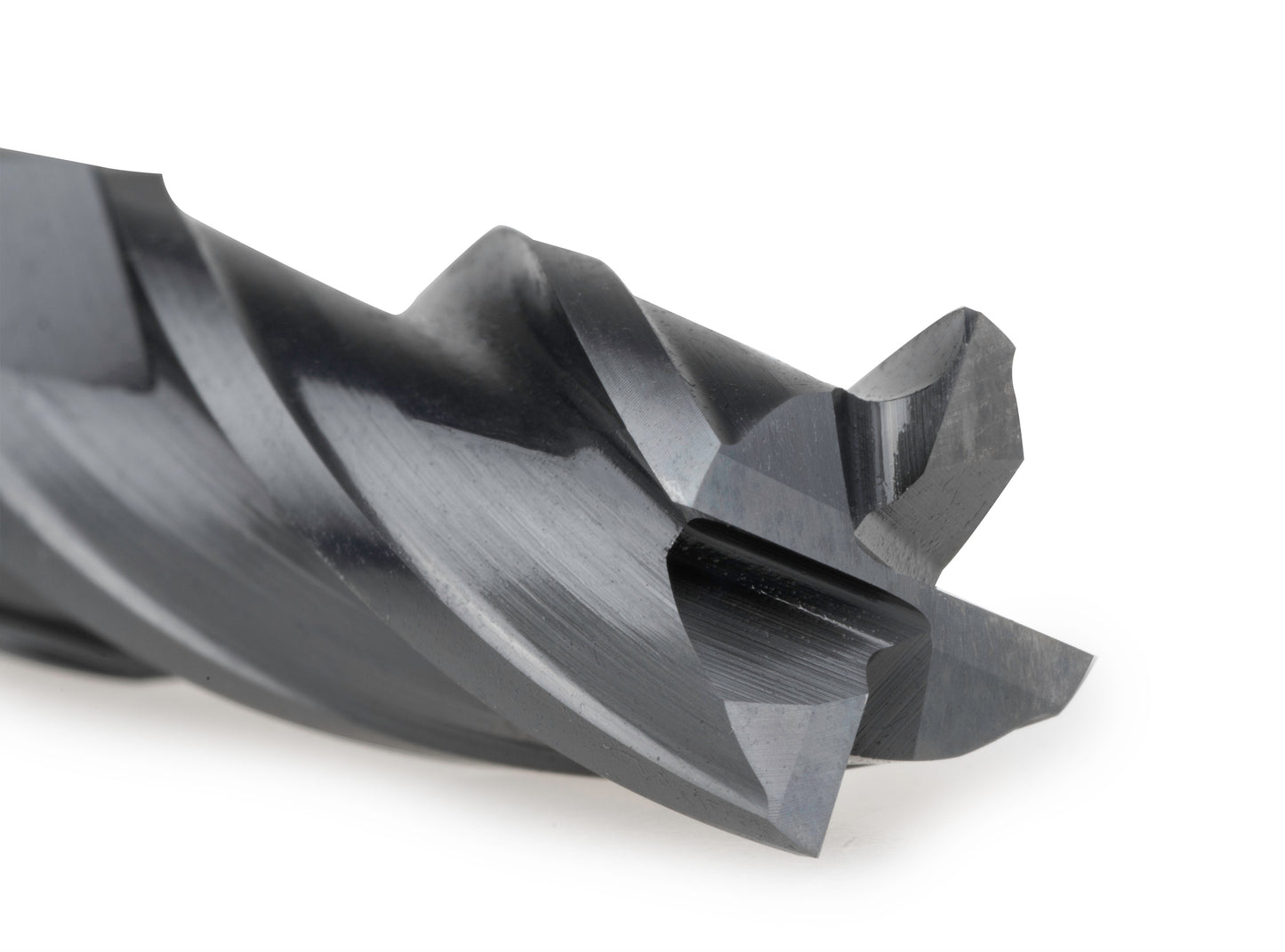

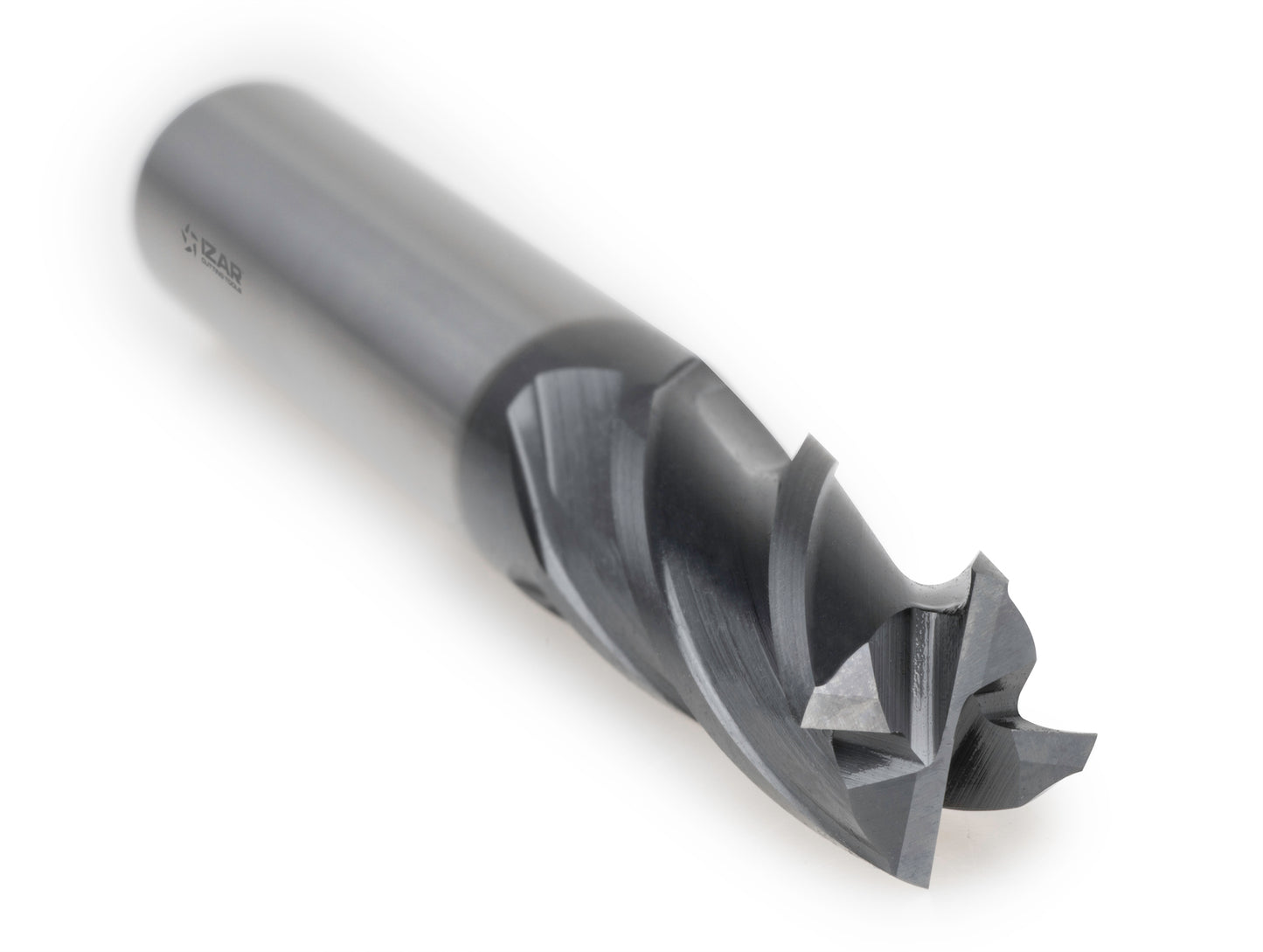

The Izar 9401 is a versatile solid carbide endmill, crafted from premium micro-grain carbide with a durable CROMAX surface coating. Its 4-flute geometry and 30° helix offer superb rigidity, excellent chip control, and smooth finish across a wide spectrum of materials. Designed to DIN 6528 N standards—and being center-cutting—this tool is perfect for both light profiling and heavy slotting in CNC and manual machining setups.

Geometry & Benefits

-

Solid micro-grain carbide construction: Enhances rigidity, wear resistance, and precision—key for tight tolerances and high-speed finishing.

-

4-flute (4Z) configuration: Balances strength and feed performance. Ideal for milling operations where smooth finishes and efficient material removal are critical.

-

30° helix angle: A moderate helix that provides an excellent mix of shear cutting action and chip movement—resulting in superior surface quality and reduced vibration, especially in steels and non-ferrous alloys.

-

CROMAX coating: A chromium-based treatment that lowers friction, reduces heat generation, and significantly enhances tool life—especially effective in abrasive or tough materials

-

Center-cutting capability: The ability to plunge directly into material makes the 9401 highly flexible—great for pocketing, contouring, and plunge-heavy operations

-

DIN 6528 N standard: Ensures consistent geometry and quality across batches—ideal for reliable performance in production environments.

Typical Uses & Applications

-

General finishing and profiling across materials such as steels, stainless steel, cast iron, aluminum, and plastics—thanks to its versatile coating and geometry

-

Plunging, slotting, and contouring in CNC milling machines, machinists’ mills, and production centers—where flexibility and surface finish matter.

-

Suitable for both CNC and manual operations, as well as for high-speed machining, thanks to its carbide substrate and CROMAX coating.

-

Available in multiple diameters (e.g., Ø6 mm, Ø8 mm, Ø9 mm, Ø14 mm), it fits any scale of machining—from fine detail to larger passwork

1mm, Cutting length 3mm, 38mm OAL, 3mm Shank

2mm, Cutting length 6mm, 38mm OAL, 3mm Shank

3mm, Cutting length 8mm, 38mm OAL, 3mm Shank

4mm, Cutting length 11mm, 50mm OAL, 4mm Shank

5mm, Cutting length 13mm, 50mm OAL, 5mm Shank

6mm, Cutting length 13mm, 57mm OAL, 6mm Shank

8mm, Cutting length 19mm, 63mm OAL, 8mm Shank

10mm, Cutting length 22mm, 72mm OAL, 10mm Shank

12mm, Cutting length 26mm, 83mm OAL, 12mm Shank

16mm, Cutting length 32mm, 92mm OAL, 16mm Shank

Couldn't load pickup availability

Low stock: 4 left

View full details